The ALTERNATOR

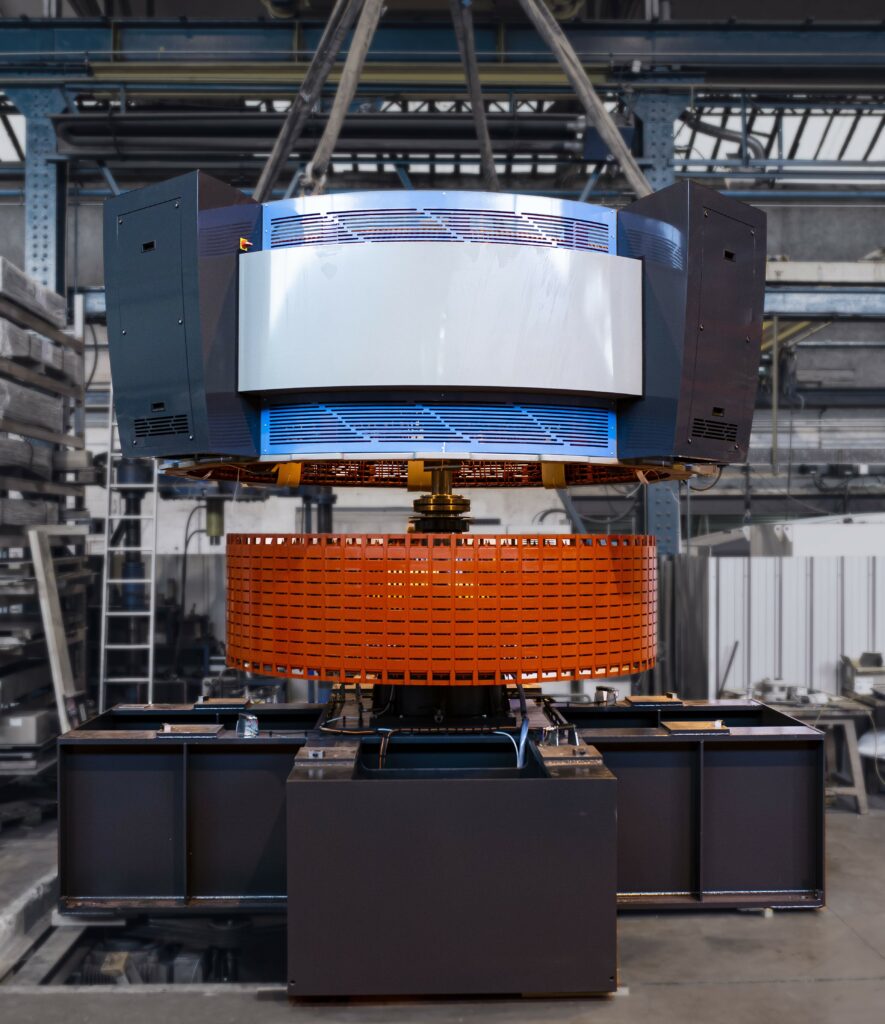

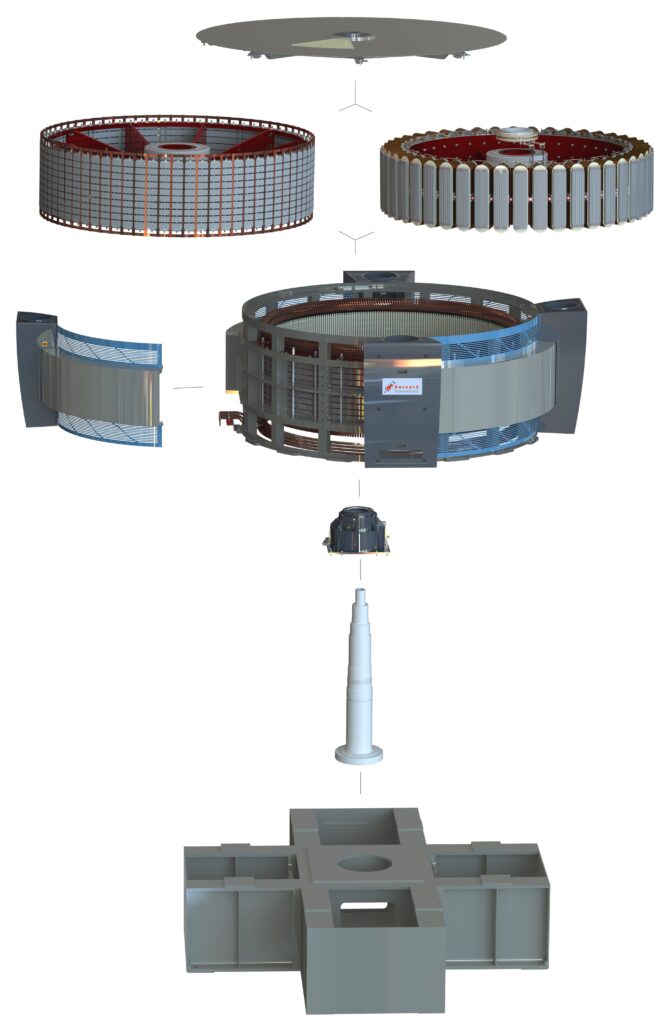

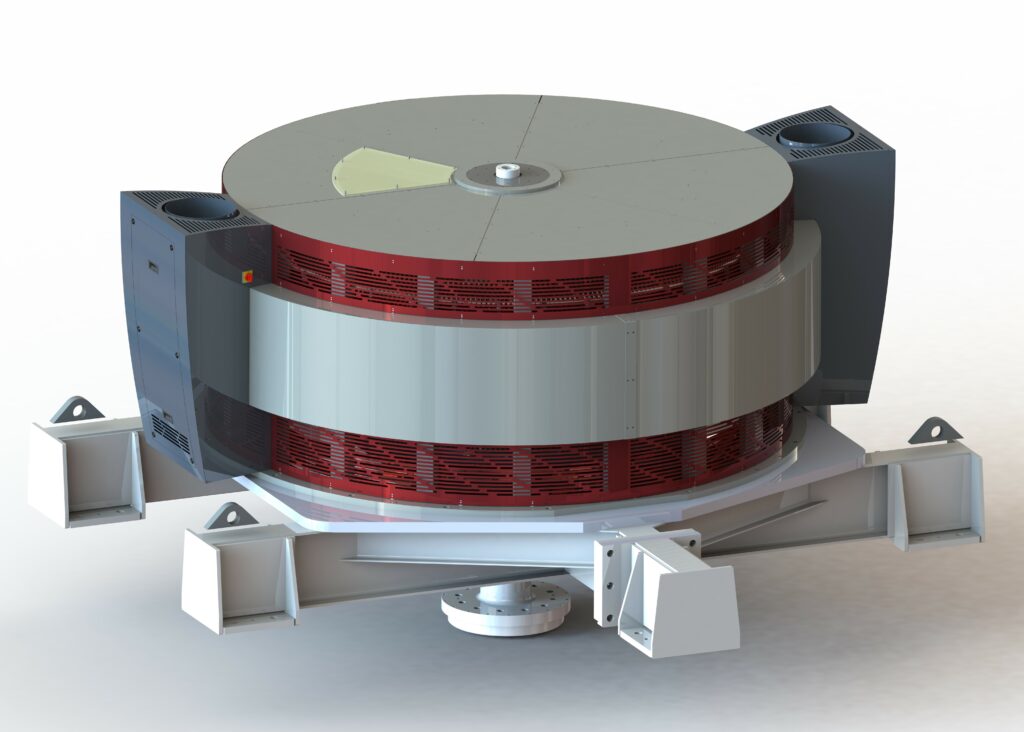

From the mechanical energy of a turbine, the alternator creates electrical energy. It is composed of a stator and a rotor that rotate at synchronous speed.

Our products range

Low speed alternators from 10 to 500 rpm and power range from 100kVA to 20MVA

Our alternators are direct-drive without multiplication, which eliminates many rotating mechanical parts..

The benefits are :

- High yield

- Less noise pollution

- High availability, less risk of breakdowns

Our expertise :

- Electrical and mechanical design and engineering

- Adaptations aux contraintes de site

- Axes : Vertical, Horizontal, Inclined

- Underwater equipment, Bulb

- Cooling : Natural/forced air, Liquid

- De nombreuses options possibles :

- Parking brake

- Frame

- Excitation cabinet

- Vibration control

- etc…

- Manufactured in our workshops in Saint-Etienne (F-42100)

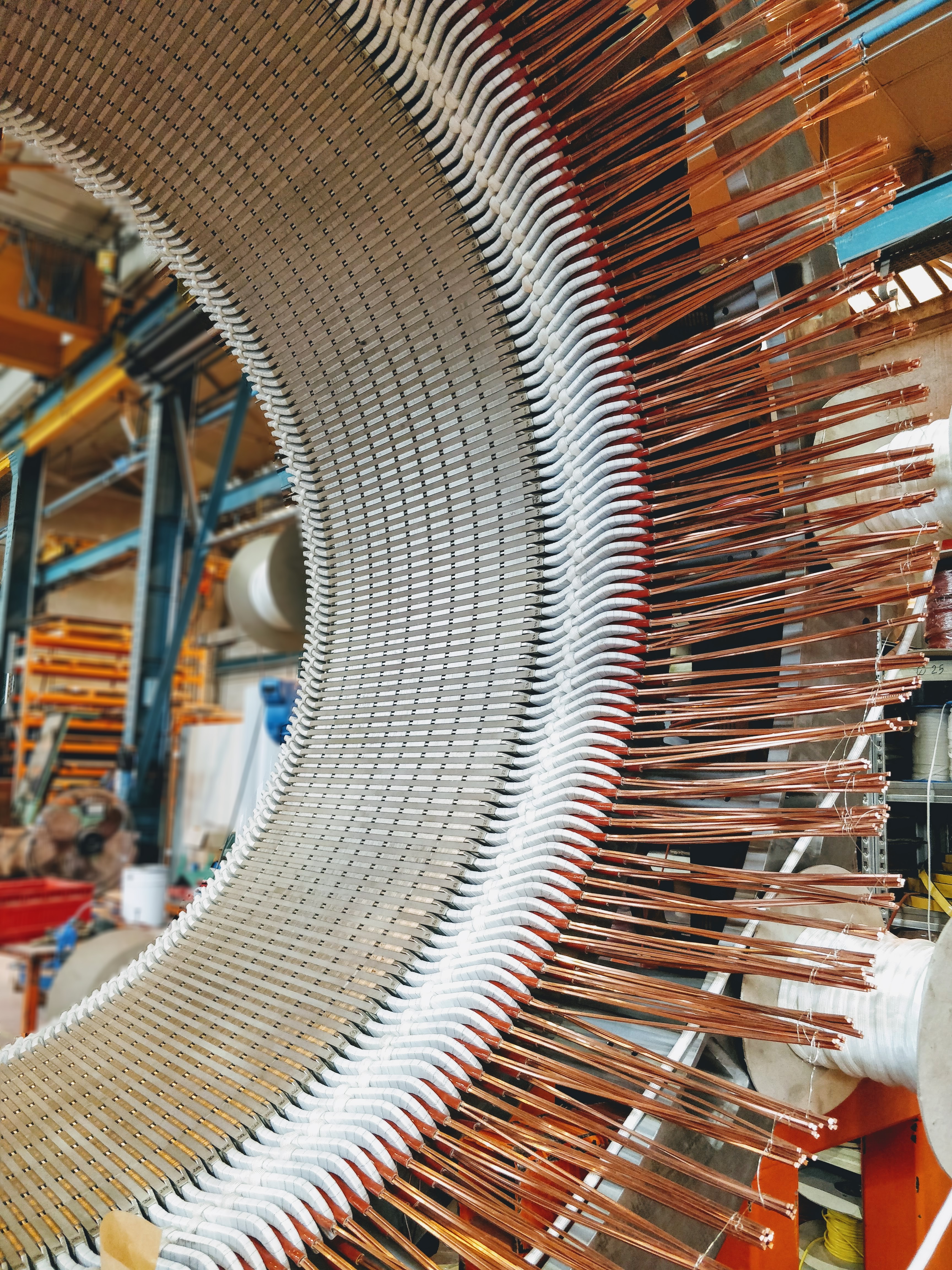

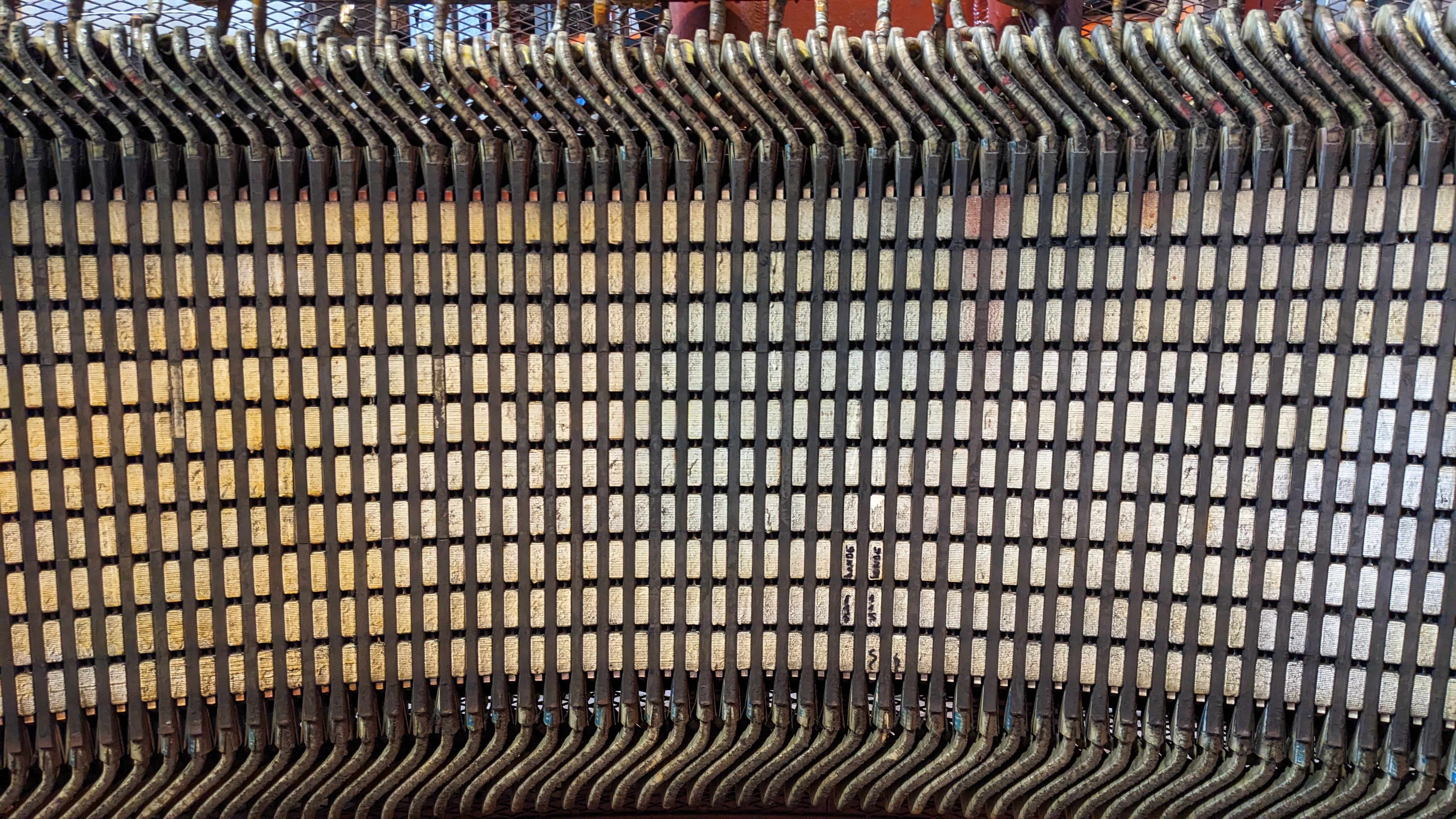

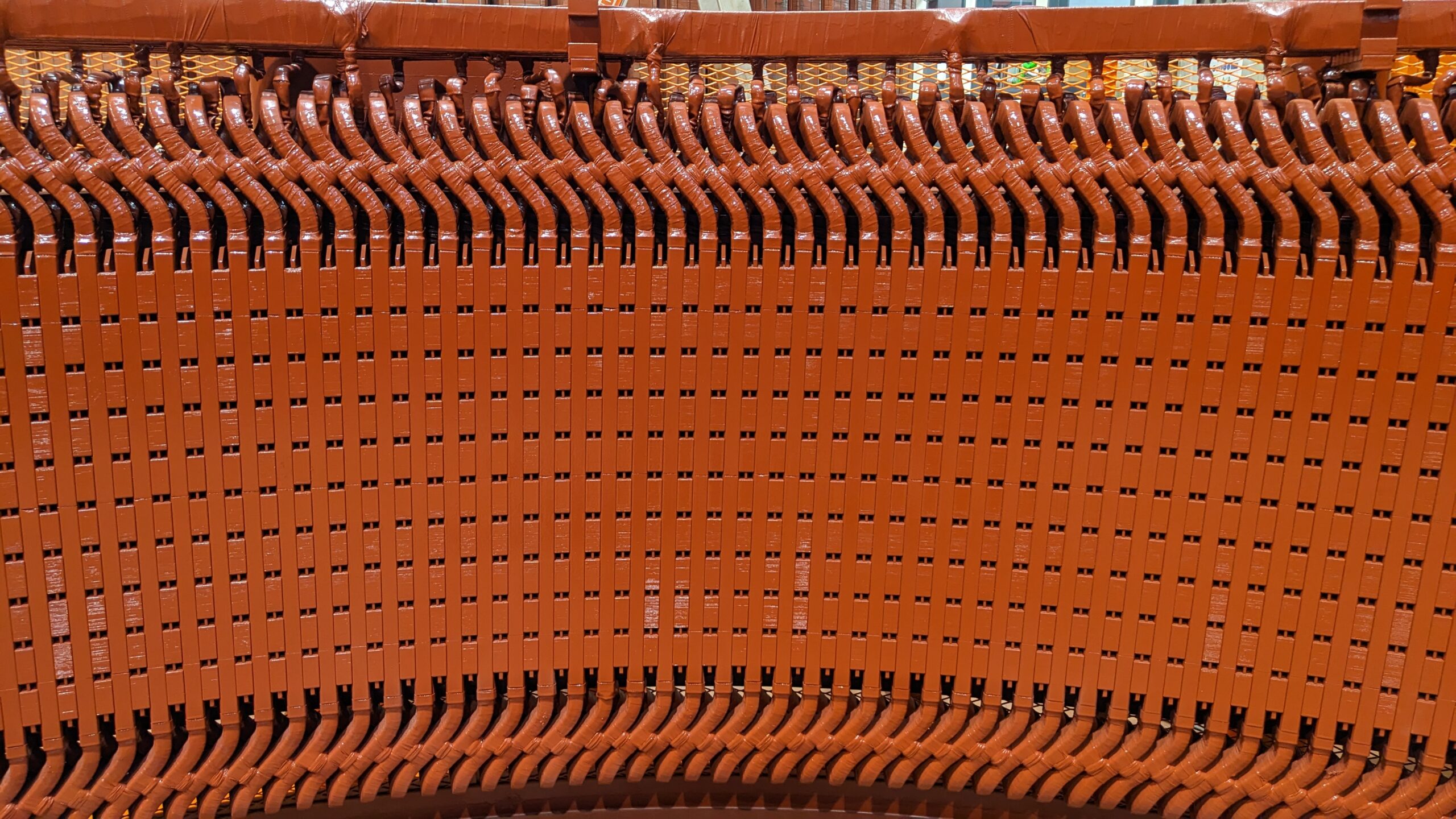

- Magnetic circuits are cut and assembled in our workshops

- Windings in our workshops

- Rotation tests for each unit in our workshops

- On site: Assembly, turbine alignment, commissioning and maintenance..

Two solutions to suit your needs

Permanent magnets generator

- Coupling cabinet (Load bank, Inverter or Direct)

- Reduced sizes

- From 100 kVA to 4 MVA

- From 10 to 500 rpm

Wound poles generator

- Possibility of static or brushless excitation with rotating diodes.

- Cos φ regulation

- From 100 kVA to 20 MVA

- From 75 to 500 rpm

10 steps to a successful project

- Product presentation

- Review of requirements

- Constraint study

- Advices

- Register your order & send a confirmation

- Deadline validation

- Machine optimization to increase efficiency

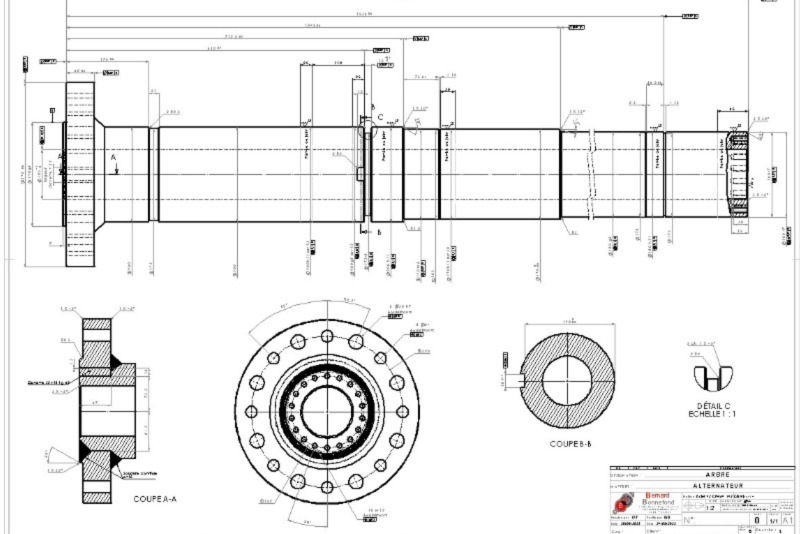

- General and interface drawings

- Manufactured in our workshops

- Magnetic circuits cutting

- Assembly

- Testing on test bed

We organize the transport(s) and plan the delivery with the customer. We offer handling solutions adapted to your site constraints.

Our technicians install and start up the generator.![]()

Our team provides maintenance and performance monitoring for all equipment sold. A full report is issued at the end of each intervention, detailing all work carried out, measurements taken and preventive recommendations.

Bernard Bonnefond it's also renovation!

Expertise and refurbished of your generator

Bernard Bonnefond and other manufacturer

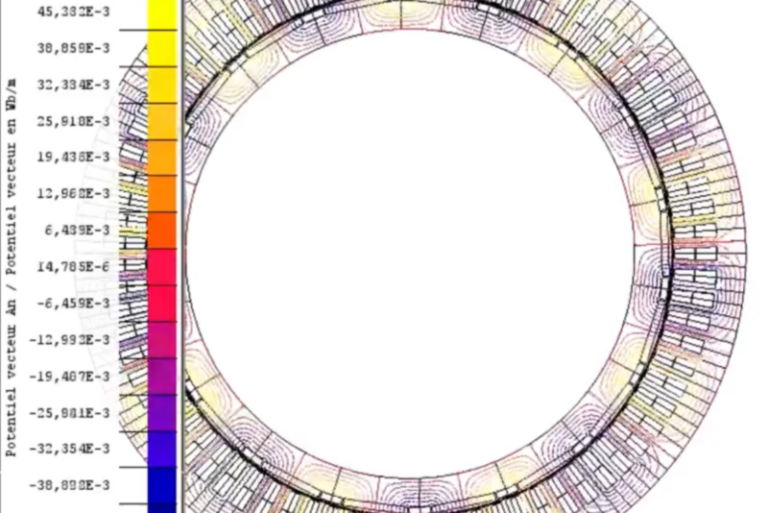

- Electromagnetic calculation to optimize electrical characteristics

- Finite element simulation with Flux2D

- Repair or replacement of magnetic circuits and winding/poles.

- Check, machining or replace mechanical parts

- Replacement or redesign bearing system

- Excitation system modification

Technical upgrading of equipment

- Added sensors for greater control.

- Cooling system modification

- Adding brake

- Modernized exterior design and improved ergonomics.

Few examples of our works

- Montgaillard, FRANCE

- Complete electrical testing before and after maintenance.

- Connections renovation from the winding to the terminal block.

- Rotor, Stator and exciter cleaning

- Drying.

- anti-flash varnish

- Bearing change

- Removal of the inertia fan mounted on the shaft (see photos, part above the rotor).

- Addition of two fans with inverters controlled by probes in the stator. Smoke test

- Mericourt, FRANCE

- Disassembly & Transport

- Sandblasting

- Dimensional and magnetic inspection

- Welding rework

- Electromagnetic calculation and efficiency optimization

- Complete overhaul of stator magnetic circuit and winding

- Cleaning & re-insulating rotor poles

- Excitation system modification

- Cooling system reconditioning

- Re-assembly and commissioning

- Cigliano, ITALIE

- Stator and rotor disassembly

- Isolation measurement

- Checking and reconditioning of stator winding wedge

- Complete cleaning of stator and rotor

- Overall drying on site

- Anti-flash varnish

- Re-assembly and commissioning

We're interested in all your technical requirements

Don't hesitate to call on us - we'll meet your challenges!

Contact us !

- Didier BERNARD - Alternators business manager

- didier.bernard@bernardbonnefond.com

- 04 77 95 30 17